What Is Electroplating? Adding Layers to Metals with Chemistry

November 16, 2024

Electroplating is a fascinating and widely used technique that applies metallic coatings to various substrates, enhancing their durability, appearance, and resistance to corrosion. This article delves into the science and applications of electroplating, demystifying the process and its significance in modern technology and industries.

1. Understanding Electroplating

Electroplating involves the deposition of a layer of metal onto a conductive surface through an electrochemical process. The process utilizes an electrical current to drive the metal ions from a solution onto a substrate. As a result, a layer of metal adheres tightly to the surface, enhancing its properties.

Common metals used in electroplating include:

- Gold: Provides a lustrous finish and excellent corrosion resistance, often used in electronics and jewelry.

- Silver: Offers good conductivity and antimicrobial properties, found in jewelry, cutlery, and electrical connectors.

- Nickel: Known for its hardness and corrosion resistance, commonly used in automotive and industrial components.

- Copper: Frequently used as a base metal for further plating due to its excellent conductivity.

These metals not only improve the aesthetic appeal of products but also enhance their functionality, making electroplating a vital process in various industries.

2. The Electroplating Process Explained

The electroplating process can be broken down into several key steps:

Step 1: Preparing the Substrate

Before electroplating begins, the substrate must be cleaned thoroughly. Any dirt, oils, or oxidation can interfere with the bonding between the metal and the substrate. Common cleaning methods include:

- Chemical cleaning agents

- Mechanical polishing

- Ultrasonic cleaning

Step 2: Electrolyte Solution Preparation

An electrolyte solution is prepared that contains the metal salts of the material to be deposited, as well as other chemicals to control the deposition process. The solution is often heated and stirred to ensure proper circulation and consistent concentration.

Step 3: Setting Up the Electroplating Cell

The electroplating cell consists of the following components:

- Anode: Made of the metal to be deposited, it dissolves during the process, providing metal ions to the electrolyte.

- Cathode: The substrate being plated, where the metal ions deposit.

- Power Supply: Provides direct current to drive the electroplating process.

Step 4: Electroplating

Once everything is set up, the direct current passes through the circuit, causing metal ions to migrate from the anode to the cathode. As the ions reach the cathode, they gain electrons and are reduced to solid metal, forming a layer on the substrate.

The thickness of the electroplated layer can be controlled by adjusting factors such as current density, time, and temperature:

- Increasing current density results in faster deposition, leading to a thicker layer.

- Longer plating times increase the overall thickness of the deposit.

- Temperature adjustments can influence the rate of deposition and the quality of the finish.

3. Advantages of Electroplating

Electroplating boasts numerous advantages that make it a preferred choice in various applications:

Enhancement of Physical Properties

Electroplating improves several attributes:

- Corrosion Resistance: A coated surface is far more resistant to oxidation and wear than untreated metals, prolonging the lifespan of items, especially in harsh environments.

- Aesthetic Appeal: The shiny, reflective finish of electroplated products enhances their visual appeal, making them popular in jewelry and decorative applications.

- Conductivity Improvement: Electroplated layers of metals like silver or gold enhance the conductivity of electronic components, playing a vital role in the electronics industry.

Cost-Effectiveness

Electroplating is generally more cost-effective than manufacturing products entirely from precious metals. By using a substrate of a less expensive material and applying a thin layer of a more costly metal, manufacturers can produce high-quality items at a fraction of the price.

Versatility

The versatility of electroplating allows for various applications across different industries:

- Automotive Industry: Used for plating components such as bumpers, trims, and connectors to enhance durability and aesthetics.

- Jewelry and Art: Commonly used to provide a shiny finish and enhance the visual appeal of jewelry and art pieces.

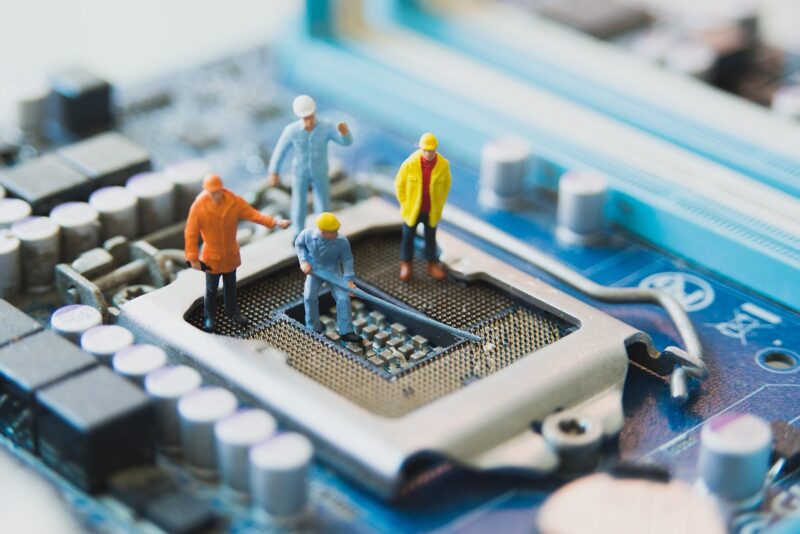

- Electronics: Essential for manufacturing high-quality connectors and circuit boards that require excellent conductivity and corrosion resistance.

4. Environmental Considerations

While electroplating has significant benefits, it is important to highlight potential environmental impacts. The process often involves toxic chemicals, which must be managed carefully to prevent environmental pollution.

Key environmental concerns include:

- Waste Management: Proper disposal and treatment of spent electrolyte and sludge are crucial to prevent soil and water contamination.

- Emissions Control: Emission of harmful vapors during the electroplating process necessitates adequate ventilation and filtration systems in plating facilities.

- Resource Conservation: Continuous recycling of metals and solutions can minimize waste and enhance the sustainability of electroplating processes.

To address these concerns, many industries are adopting green electroplating technologies that reduce or eliminate toxic substances, emphasizing the need for responsible manufacturing practices.

5. Conclusion

Electroplating is an essential technique in modern manufacturing, enhancing the properties of various materials while improving their aesthetic appeal. By utilizing electrochemistry, industries can effectively apply metal layers that resist corrosion, improve conductivity, and provide a better finish.

As technology evolves, innovations in electroplating processes and materials will ensure sustainable practices and further enhance applications across diverse sectors.

Understanding electroplating not only highlights its practicality but also reveals the intricate chemistry that plays a role in achieving functionally superior materials. Whether in automotive, electronics, or fashion, electroplating remains a vital component of modern industry.