How Handguns Are Made: A Look at the Intricate Craftsmanship of Firearms

November 12, 2024

The manufacturing of handguns is a meticulous process that combines precision engineering, skilled craftsmanship, and innovative technology. Each component of a handgun must be shaped, treated, and assembled with the utmost care to ensure reliability, safety, and performance. This article delves deep into the various stages of handgun manufacturing, from initial design to final assembly and testing.

1. The Design Phase: Concept to Blueprint

The journey of a handgun begins at the design phase, where engineers and designers create blueprints based on functionality, ergonomics, and aesthetics. Key elements to consider include:

- Caliber Selection: The caliber determines the size, power, and intended use of the handgun. Common calibers include .22 LR, 9mm, .40 S&W, and .45 ACP.

- Material Selection: Handguns are typically made from steel, aluminum, or polymer, depending on the intended use and budget. Each material offers different benefits in terms of weight, durability, and cost.

- Ergonomics and Aesthetics: The design must be comfortable to hold and use while appealing to consumers. Considerations such as grip angle, texture, and placement of controls are crucial.

With these aspects in mind, CAD (Computer-Aided Design) software is utilized to create detailed 3D models, allowing engineers to visualize the handgun’s structure and functionality before production begins.

2. Material Preparation: Shaping the Future Firearm

After the design is finalized, the next step is sourcing and preparing materials. The most common materials used in handgun manufacturing are:

- Steel: Known for its strength and toughness, steel is used for critical components like the slide and frame. Different types of steel (like stainless or carbon) offer varying resistance to corrosion and wear.

- Aluminum: Lightweight and sturdy, aluminum is often used in the frames of some handguns to reduce overall weight without sacrificing strength.

- Polymer: Many modern handguns feature polymer frames due to their lightweight nature and ability to withstand harsh conditions. Polymeric materials also offer flexibility in designs and colors.

Once the materials are sourced, they undergo a variety of processes like cutting, machining, and forging to shape them into precise components needed for the handgun. For instance, metal parts may be machined using CNC (Computer Numerical Control) machines to ensure accuracy down to the thousandth of an inch.

3. Precision Machining: From Block to Component

Precision machining is a critical step in the handgun manufacturing process. Here, raw materials are transformed into functional components, including:

- Barrel: The barrel must be rifled to impart spin on the bullet, enhancing accuracy. This process involves cutting grooves into the inner surface of the barrel.

- Slide: The slide houses the barrel and provides a mechanism for ejecting spent cartridges and chambering new rounds. Machining the slide involves creating precise cuts and grooves for optics, sights, and safety features.

- Frame: The frame serves as the handgun’s backbone, housing the trigger and magazine. It requires careful machining to fit components securely.

Machining can involve several techniques, such as milling, drilling, and grinding, where each method plays a role in achieving the desired contour and feature specifications.

4. Heat Treatment: Strengthening the Components

After machining, the components undergo heat treatment processes to enhance strength, hardness, and resistance to wear. Common methods include:

- Hardening: By heating the metal to a specific temperature and then cooling it rapidly, manufacturers can create a hard outer shell while retaining ductility on the inside.

- Tempering: This process involves reheating hardened materials to relieve stresses and improve toughness without losing hardness.

- Surface Treatments: Techniques such as nitriding or bluing can be applied to improve corrosion resistance and appearance.

Heat treatment is essential to ensure that the handgun can withstand the pressure and heat generated during firing, thereby enhancing the lifespan of the firearm.

5. Assembly: Bringing It All Together

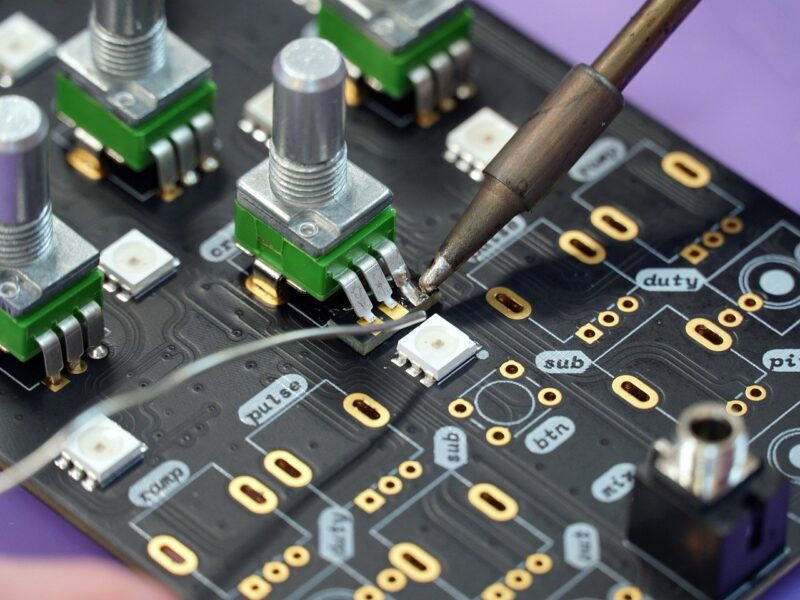

Once all components are prepared, the assembly process begins. Skilled technicians carefully assemble the handgun piece by piece, ensuring each part functions correctly together.

Key steps during assembly include:

- Installing the Barrel: The barrel is fitted into the slide with tight tolerances to minimize movement and maximize accuracy.

- Adding the Trigger Mechanism: The trigger assembly is integrated into the frame, where it must engage the firing pin reliably without any hiccups.

- Final Fit and Function Check: With the major components in place, a thorough inspection is carried out to confirm everything is assembled correctly, and the actions function smoothly.

Assembly requires patience and skill, as any small error can lead to malfunctions in the final product.

6. Testing: Ensuring Safety and Performance

Once assembled, each handgun undergoes rigorous testing to ensure safety, accuracy, and reliability. Areas typically scrutinized include:

- Functionality Tests: The firearm is tested to ensure all mechanisms operate properly—this includes firing a set number of rounds to check for any malfunctions.

- Accuracy Tests: Targets are used to determine the precision of each handgun. Groups of shots are measured to assess how tightly they cluster on the target at different distances.

- Safety Checks: Special attention is given to safety mechanisms like manual safeties and drop tests to ensure the firearm will not malfunction under standard handling conditions.

Only after passing all tests can a handgun be deemed ready for sale, ensuring buyers receive a product that meets strict quality standards.

7. Final Touches: Finishing and Quality Control

Upon passing all functional tests, handguns receive final touches before packaging. This may include:

- Finishing Processes: Depending on the manufacturer’s requirements, finishes like anodizing, painting, or coating may be applied for added protection against wear and corrosion.

- Quality Control Checks: Final inspections are done to catch any cosmetic or functional issues before distribution. Only those meeting quality standards move to market.

This phase is essential in maintaining the credibility of the brand and ensuring customer satisfaction.

Conclusion: The Craftsmanship Behind Every Handgun

Understanding how handguns are made allows us to appreciate the intricate craftsmanship involved in their creation. From the initial design to final testing, each phase of production is vital in ensuring that the firearm is safe, reliable, and ready for use. The dedication and skill of those involved in this process are what ultimately result in the high-quality handguns that enthusiasts and professionals rely on. Whether for sport, personal defense, or collection, the craftsmanship behind handguns reflects a rich tradition of firearms manufacturing that continues to evolve today.