How 3D Printing is Transforming the Manufacturing Industry

November 13, 2024

3D printing, also known as additive manufacturing, is revolutionizing how products are created and manufactured in various industries. From automotive to healthcare, and from aerospace to consumer goods, 3D printing technology is enabling manufacturers to innovate, reduce costs, and improve production efficiencies. This article delves into how 3D printing is transforming the manufacturing landscape, the benefits it offers, and what the future holds for this groundbreaking technology.

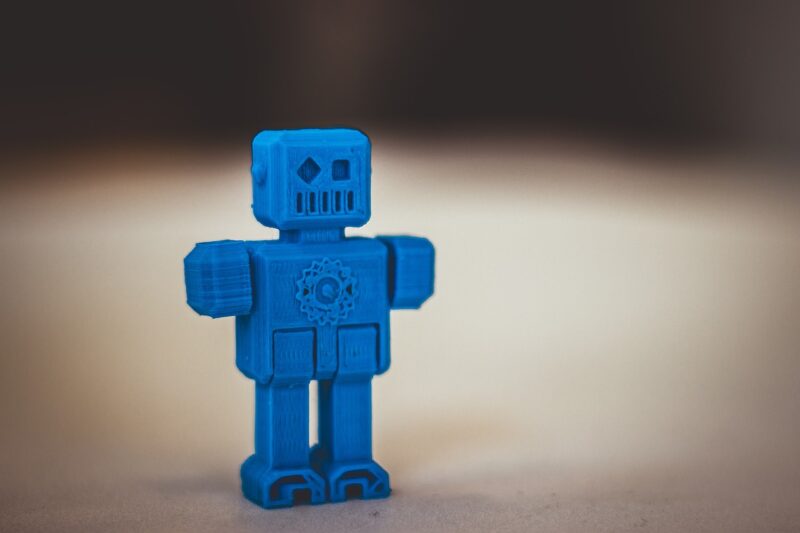

1. The Basics of 3D Printing

3D printing is a process that creates three-dimensional objects from a digital file. This technology works by layering materials such as plastics, metals, or bio-materials to form complex shapes and structures. Unlike traditional manufacturing methods that involve subtracting material (like machining or milling), 3D printing builds objects from the ground up. Popular materials used in 3D printing include:

- Plastics: Thermoplastics and photopolymers are commonly used for prototypes and consumer products.

- Metals: Various metal powders are utilized in processes like Selective Laser Sintering (SLS) for durable functional parts.

- Ceramics and Composites: These materials are often used for specialized applications such as dental implants or aerospace components.

Understanding the fundamentals of 3D printing sets the stage for appreciating its impacts on the manufacturing industry as a whole.

2. Cost Efficiency and Material Savings

One of the most significant advantages of 3D printing is its cost efficiency. Traditional manufacturing often involves expensive tooling and molds; however, 3D printing eliminates most of these costs. Here’s how it saves money:

- Reduced Waste: Since additive manufacturing only uses the material needed to create an item, it’s more sustainable and minimizes waste compared to subtractive methods which can waste up to 90% of raw materials.

- Lower Labor Costs: Reduced labor intervention is required once a 3D printing setup is configured, leading to lower workforce costs over time.

- Shortened Production Runs: With 3D printing, companies can produce small batches of products without high upfront costs, allowing for easier adjustments and customizations as needed.

These cost benefits make 3D printing an attractive option for manufacturers, especially for startups and small to medium-sized enterprises looking to innovate without breaking the bank.

3. Customization: A New Era of Tailored Manufacturing

Personalization is a key trend in consumer markets, and 3D printing plays a vital role in enabling customization on a mass scale. Manufacturers have recognized the potential of tailored products by leveraging 3D printing techniques, which allow them to:

- Create Unique Products: Whether it’s custom prosthetics in healthcare or bespoke automotive parts, 3D printing can produce items that meet specific customer requirements.

- Quick Prototyping: Designers can quickly create functional prototypes to test their ideas without the need for costly molds or long lead times.

- Design Innovation: The freedom of design that 3D printing offers allows engineers to create highly complex structures that are lighter and more efficient than traditional designs.

Customization is no longer limited to high-end markets; with 3D printing, products from everyday household items to sophisticated machinery can be tailored based on user preferences.

4. Industries Impacted by 3D Printing

The potential applications of 3D printing are virtually limitless, impacting various sectors:

- Healthcare: From creating personalized implants and prosthetics to developing bioprinted tissues, this industry benefits significantly from precise, customized solutions.

- Aerospace: Major companies like Boeing and Airbus are using 3D printing for lightweight components that improve fuel efficiency and reduce costs in aircraft manufacturing.

- Automotive: Manufacturing complex parts quickly and efficiently through 3D printing has accelerated prototyping, significantly shortening the time from concept to production for new car designs.

- Consumer Goods: Companies are utilizing additive manufacturing for a variety of products ranging from eyewear to footwear, enhancing consumer options in design and features.

The adaptability of 3D printing means that its influence will extend well beyond these industries, impacting virtually every aspect of manufacturing in the years to come.

5. Challenges and Considerations

While 3D printing offers many benefits, there are also challenges to address:

- Material Limitations: Not all materials can be used in additive manufacturing, and finding the right material for specific applications can be difficult.

- Intellectual Property Risks: As 3D printing makes replicating products easier, protecting designs and products from unauthorized reproduction poses legal challenges.

- Quality Control Issues: Maintaining consistent quality and standards in the 3D printing process can be challenging, especially for industrial applications where precision is critical.

Manufacturers must carefully navigate these challenges to reap the full benefits of 3D printing technology.

6. The Future of 3D Printing in Manufacturing

The future of 3D printing in manufacturing looks promising. As technology evolves, we can expect:

- Increased Speed and Efficiency: Innovations such as multi-material printing and faster printing speeds will make the process even more efficient.

- Wider Material Options: Ongoing research will lead to new materials that may enhance the functionality and durability of 3D printed products.

- Integration with Industry 4.0: The combination of 3D printing with AI, IoT, and automation technologies will create smarter manufacturing systems that optimize production workflows and increase efficiency.

As manufacturers continue to explore the capabilities of 3D printing, the industry is on track to witness unparalleled growth and innovation.

Conclusion

3D printing is not just a trend; it is a transformative force reshaping the future of manufacturing. Its potential to reduce costs, enhance customization, and revolutionize production processes is unrivaled. Manufacturers who embrace 3D printing technology are better positioned to innovate and compete in today’s fast-paced market. As we look forward, expect 3D printing to become a cornerstone of modern manufacturing, inherently changing how products are designed, produced, and delivered to consumers across the globe.